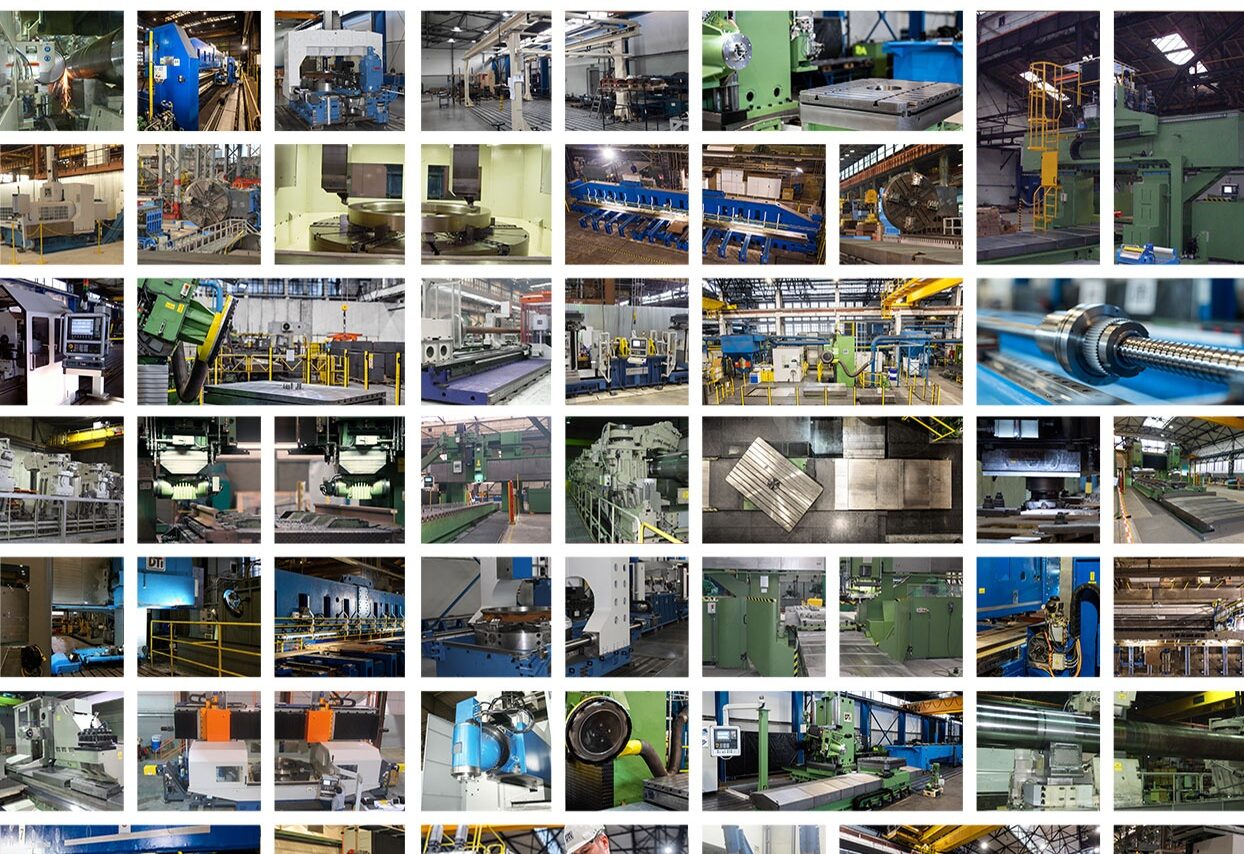

CNC Automated machining lines

PROJECTS

We are a partner in the implementation of new technologies and production solutions in various industries.

Torque up to 6.900 Nm

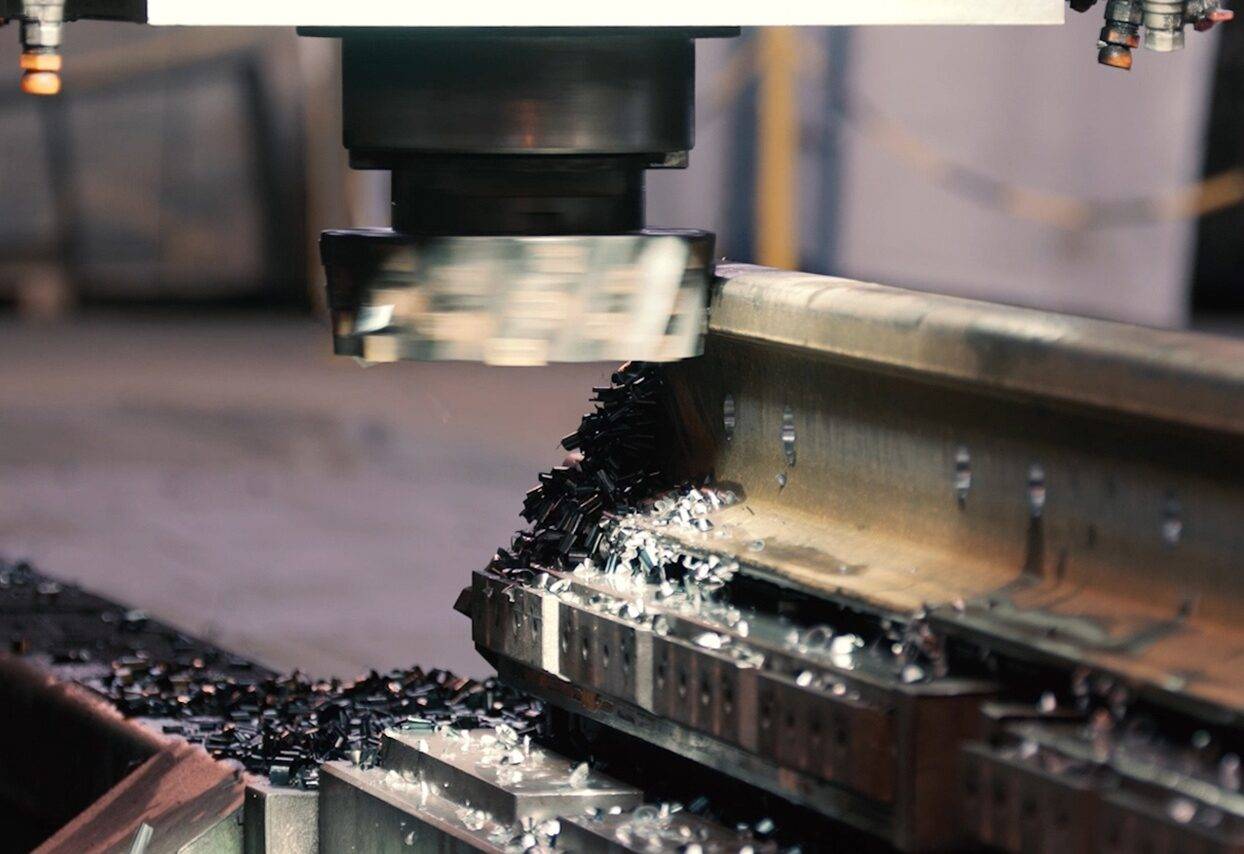

CUTTING

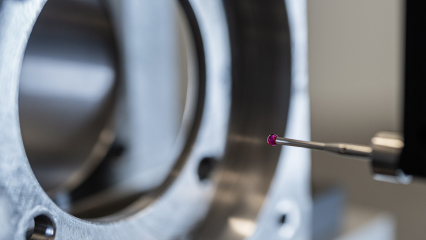

We combine power and accuracy into a sophisticated machine to meet the most demanding challenges. Our machine tools are designed for demanding applications in various industrial sectors

Machining of hard materials

Our vertical and horizontal machine tools can handle the most demanding heavy machining.

Flexibility for every process

Adaptable to a wide range of applications, DTI machines are used in industries that require reliability and precision.

Over 160 projects

Our portfolio includes over 160 heavy-duty CNC machines tailored to the needs of our customers - designed with the challenges they face in mind.

We understand the needs of the industry.

For more than 33 years, we have been creating reliable heavy-duty machine tools for machining, using the knowledge and skills of our engineers and in-depth knowledge of market needs.

Heavy-duty machine tools. Design, delivery and machining with DTI

Your specific requirements are our goal. Welcome to the world of DTI, where we have been designing and supplying heavy-duty machine tools for over 33 years. We know your industry and perfectly understand its needs. That’s why we are specialists in individual solutions – tailored to your business.

Heavy-duty machine tools. Power and accuracy

Smart solutions for tomorrow’s tough applications – this is not only our motto, but our guiding light which has ensured our success for many years.

Our mission? Research your needs, then design and deliver a heavy-duty machine tool or a complete automated machining line that will serve you for many years, ensuring performance and reliability, safety, ease of operation and maintenance.

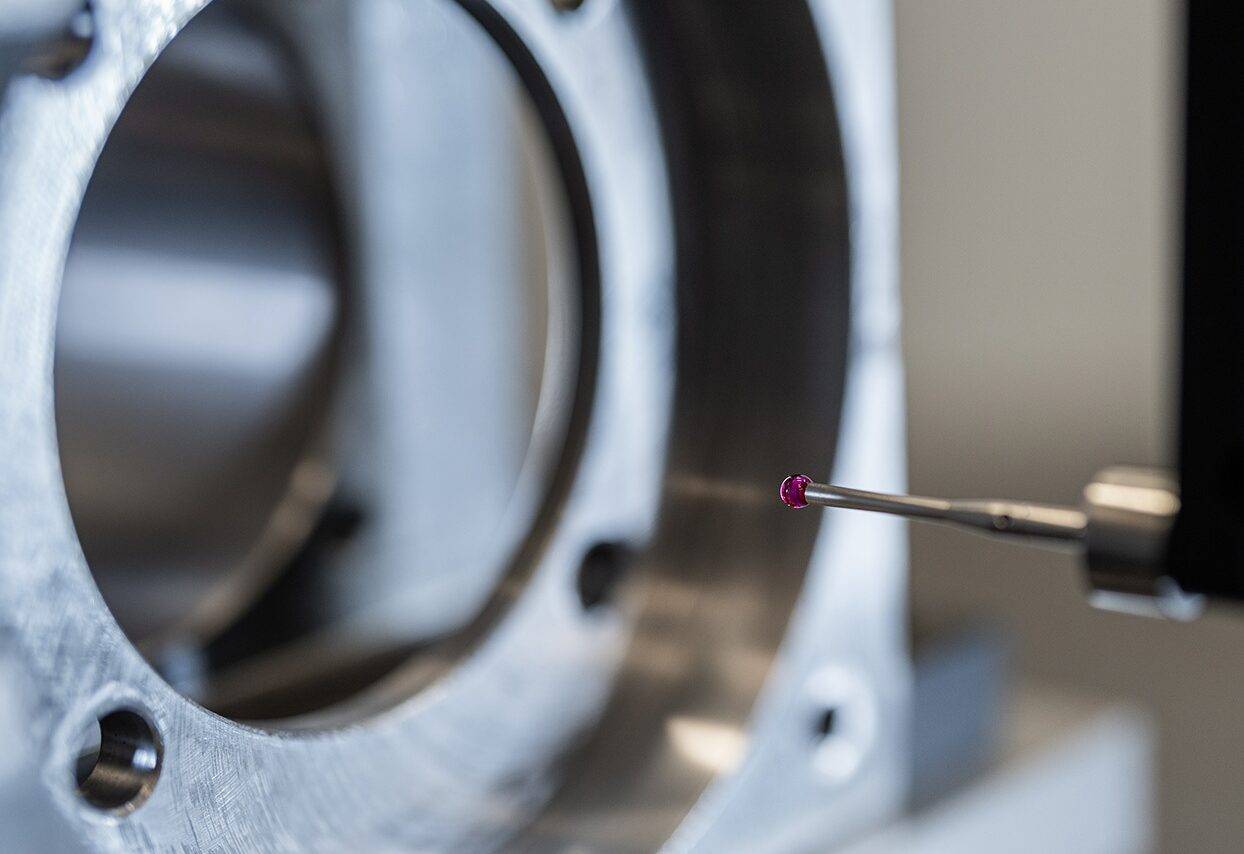

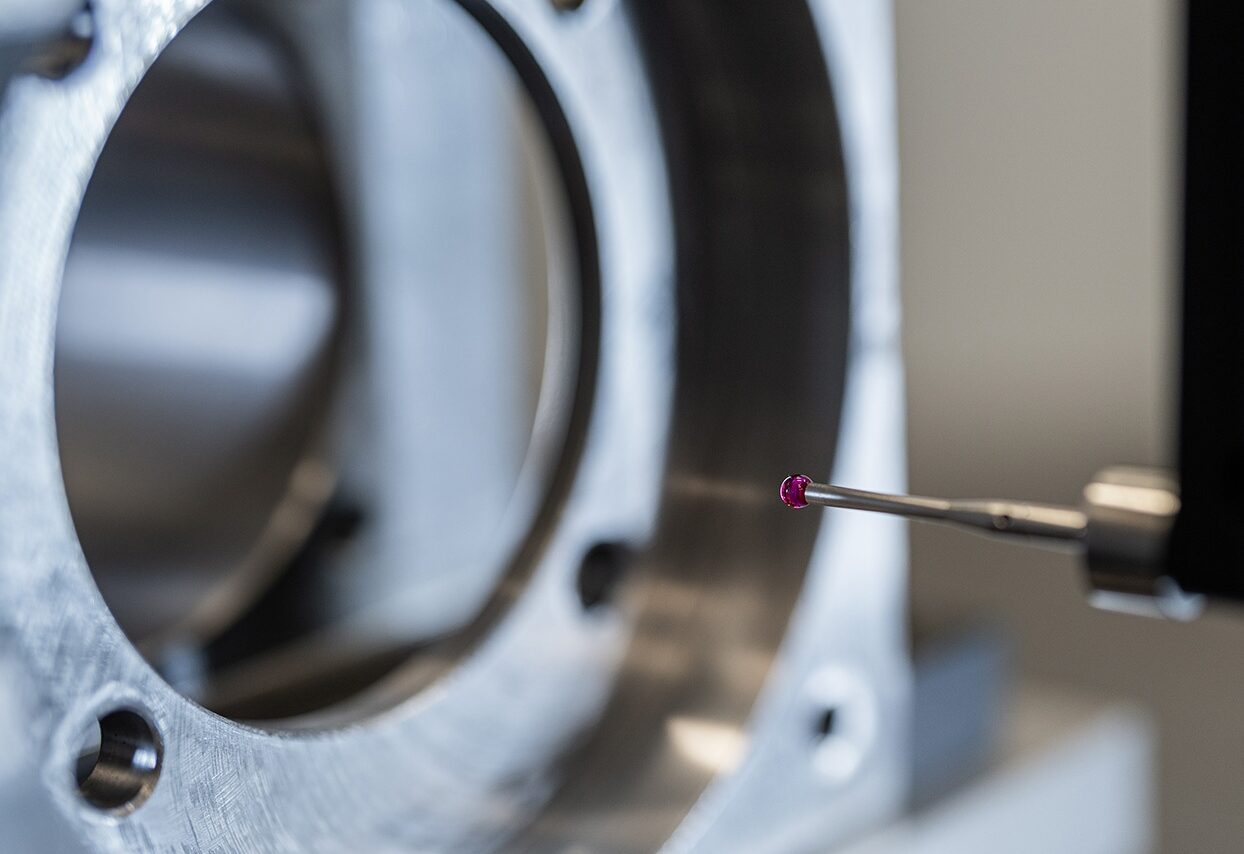

All this is possible thanks to our team of engineers who strive to achieve the perfect balance between power and accuracy of every single machine tool.

Heavy-duty machine tools. Markets

Reliability, machining accuracy, exceptionally rigid design and a range of personalization options – these are the trademarks of heavy-duty DTI machine tools.

We supply our machine tools to those industries where it is particularly important to have dedicated solutions for heavy cutting. DTI machine tools have been operating in industries such as: railways, metallurgy, energy industry, forgings and shipbuilding industry.

Design of heavy-duty machine tools

We start designing heavy-duty machine tools with a deep understanding of your technological and operational needs – they inspire us to innovate and use our many years of technical experience.

Using advanced CAD tools and working with component industry leaders, we create heavy-duty machine tools that are not only powerful and precise, but also designed for efficiency, ease of operation and maintenance, as well as operational safety.

Let our team of engineers take care of every detail, creating a machine tools that will exceed your expectations and serve you for many years, increasing the efficiency and profitability of processes in your company.

Delivery of heavy-duty machine tools

We know perfectly well how important it is to deliver heavy-duty machine tool on time. Efficient and quick delivery of the machine tool allows you to maintain the continuity of production processes, eliminating the risk of downtime and related costs.

That’s why our machine tools reach you exactly when you need them. Our experienced logistics team guarantees that each machine tool will be safely transported and delivered directly to your workplace – regardless of where you are.

By working with trusted logistics partners, we ensure an effective and hassle-free delivery process. Enjoy peace of mind knowing that we will take care of everything – from production to delivery directly to your plant.

Tell us about your project

Reliable heavy-duty machine tools are at your fingertips – just take the first step and contact us. Our experts are ready to answer all your questions, discuss individual requirements and propose solutions that will best meet your expectations.

PRODUCTS

DTI machine tools stand out due to their reliability, exceptional heavy-duty design and customization.

SHOW PRODUCTS ⟶

SECTORS

DTI has developed special machine tools for sectors where heavy-duty solutions are requested.

SHOW SECTORS ⟶

We are launching the DTI TechAcademy – discover with us the secrets of designing heavy-duty machine tools

DTI TechAcademy this project aims to introduce the world of heavy DTI machine tools. As part of our training center – on the website DTI TechAcademy, we will present comprehensive, substantive materials focusing on one of the features of heavy machine tools, we will discuss many issues related to the proper design, production and modernization...

We would like to invite you to read the January issue of BusinessPl, where you will learn, among others, about the beginnings, evolution and flagship projects of DTI.Karolina Sywak, Managing Director, will present the history of the company

Design Technologies International Sp. z o. o. (DTI) – Three decades of innovation in the world of special machine tools. Design Technologies International Sp. z o. o., known as DTI, is a company based in Racibórz, which has been proudly operating in the industry of special heavy duty machine tools since 1991. DTI supplies machine tools perfectly tailored...

Modernization for the world leader in the production of machines for the paper industry

We have just completed the modernization of a milling machine with a movable crossrail manufactured by WALDRICH SIEGEN PORĘBA in 1972. Our client, a leader in the production of machines for the paper industry, can again machine complex workpieces with max dimensions of 1600mm x 8000mm x 2000mm. After signing the contract, we spent the first 8 months...

EMO 2023 is behind us

We are extremely grateful for all the valuable comments, insightful conversations and new contacts we have established. Your support fuels our commitment to providing custom, heavy-duty machine tools tailored to your needs. Please don’t hesitate to contact us if you have any questions or need more information. We are here for you! Let’s continue the...

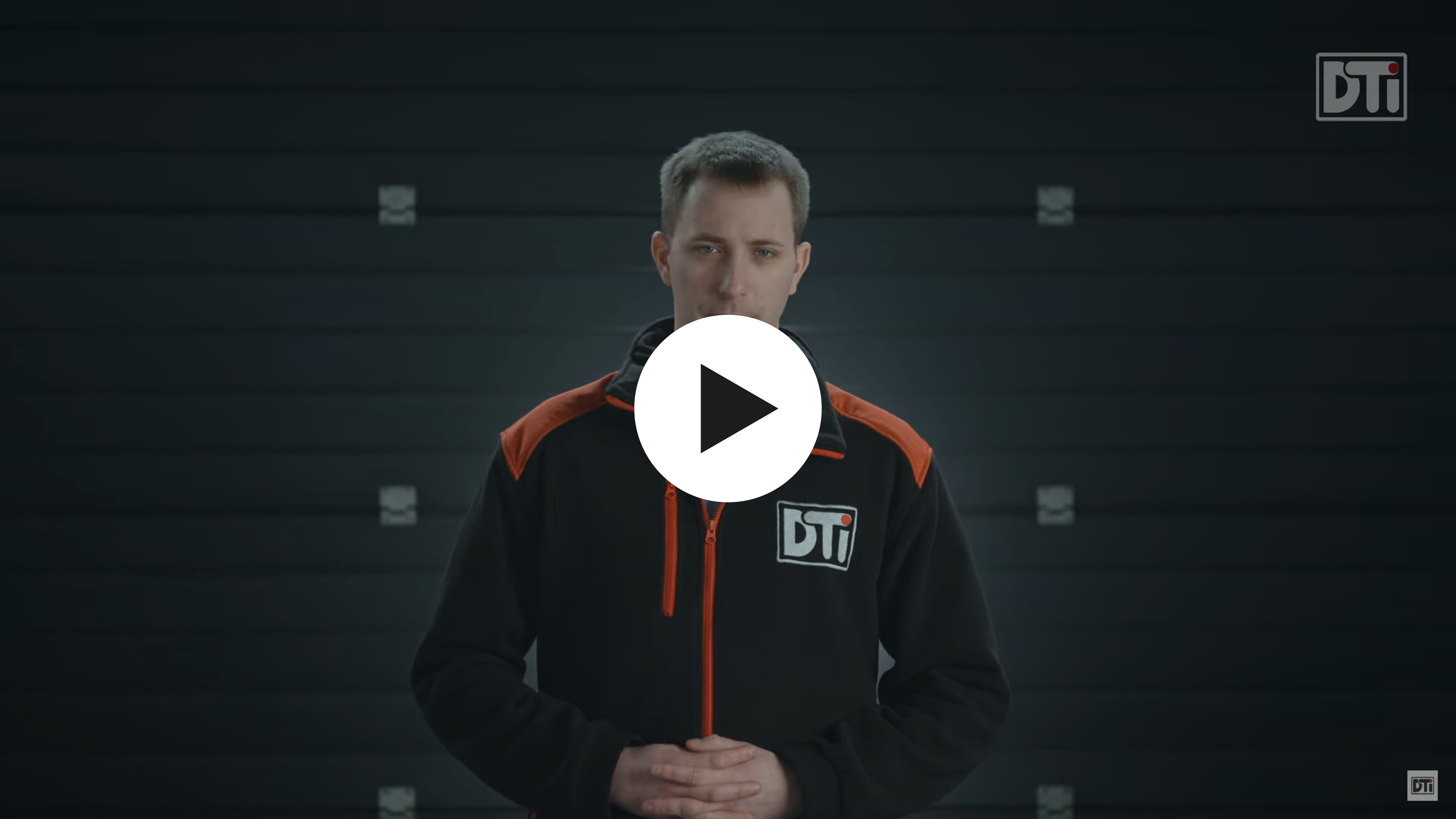

What are the characteristic of cast iron?

We invite you to watch the first video made as part of the DTI Tech Academy series! In the video, our Mechanical Engineer will talk about the properties of cast iron used in the production of DTI machine tools.

Sed ut perspiciatis unde omnis iste natus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Sed ut perspiciatis unde omnis iste natus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.