Products

5HMC

5+1 HMC

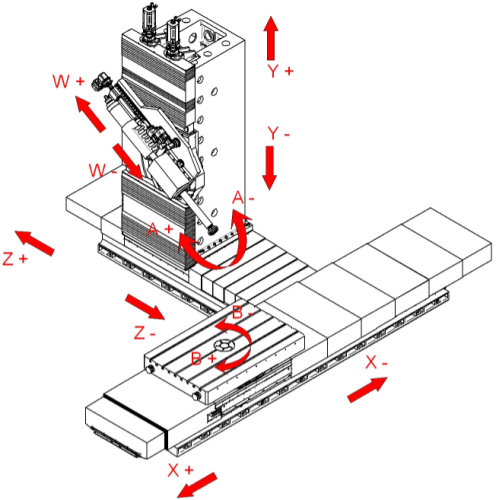

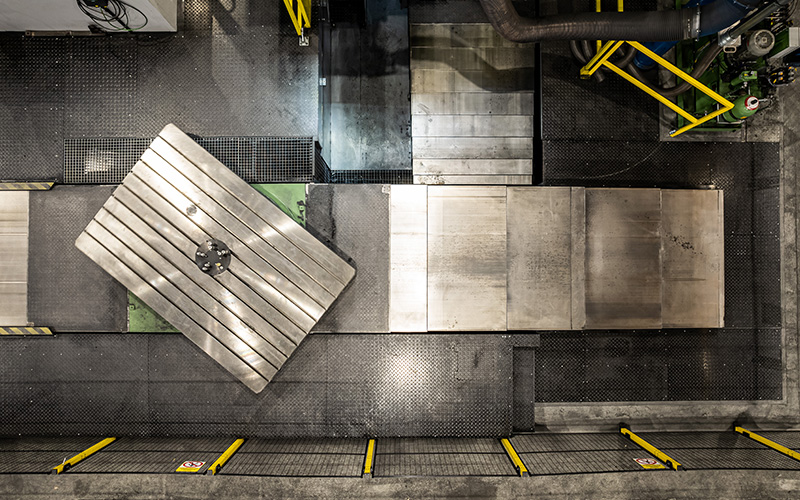

Each size of our heavy-duty 5 axis horizontal milling centers with swiveling spindle unit we can configure as a custom machine solution. This includes adding a boring bar and turning 5 HMC into 5+1 HMC swiveling boring mill.

5 HMC

MAIN FEATURES

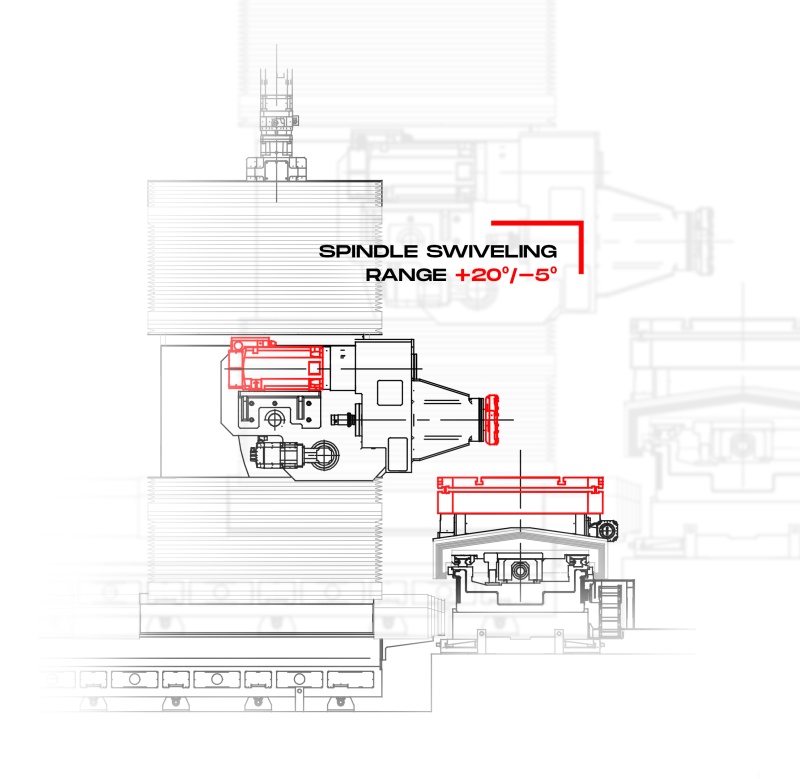

- Swiveling spindle unit in standard execution

- All main components made of grey iron casting

- High rigidity ensures tight tolerance maintained over time

- Outstanding precision

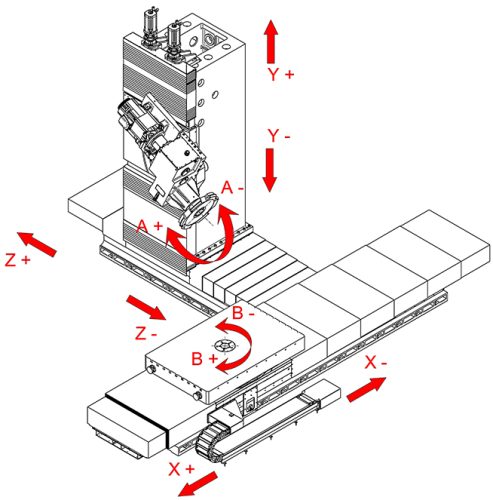

- “Y” axis double gantry feed drive with electronic compensation of the spindle axis leveling

- “A” double feed drive with backlash electronic compensation (“master slave”)

- “B” double feed drive with backlash electronic compensation (“master slave”)

- Beds and column ways can be slide (steel hardened and ground), hydrostatic or linear

- Heidenhain linear and rotary scales

5 HMC

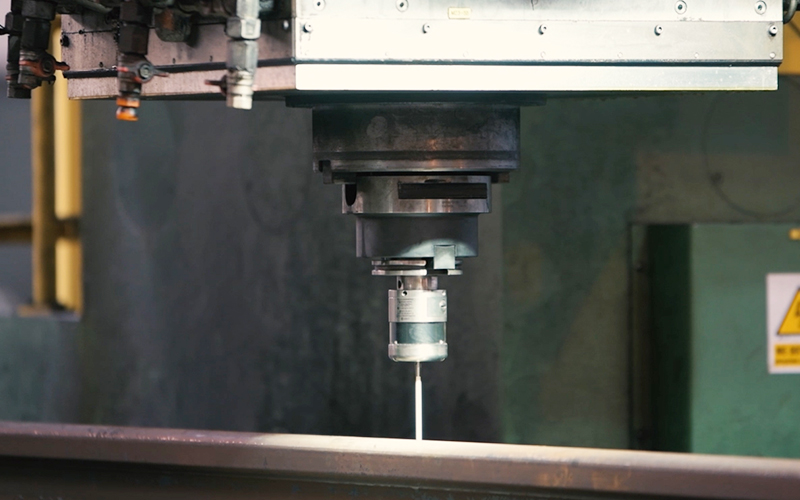

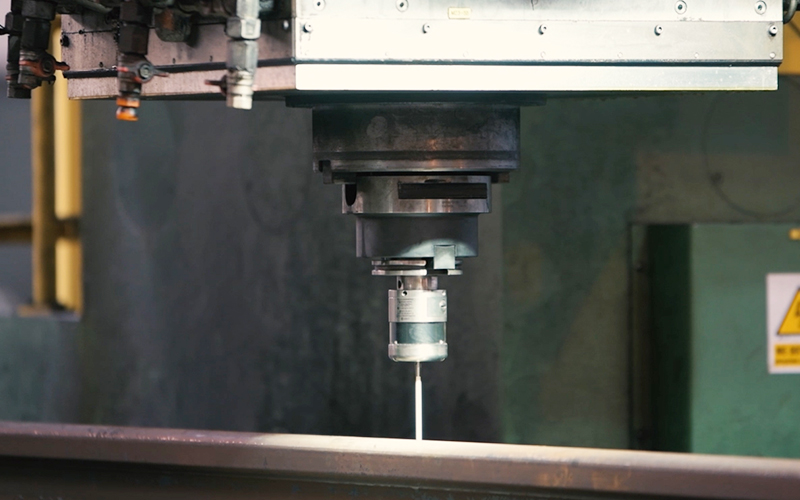

5 HMC is a 5 axis horizontal milling center with swiveling spindle unit dedicated for heavy cutting.

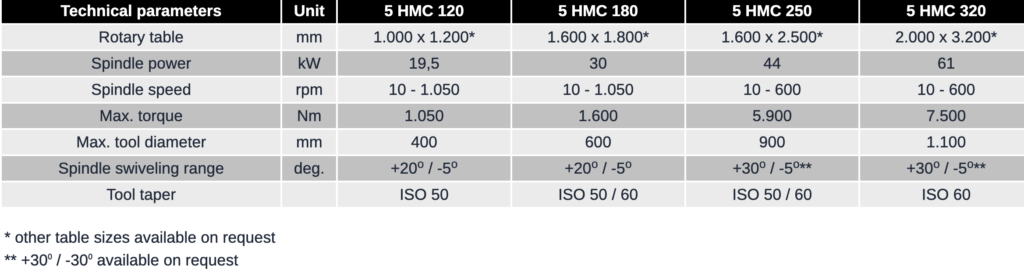

5 HMC

TECHNICAL

SPECIFICATION

| Technical parameters | Unit | 5 HMC 120 | 5 HMC 180 | 5 HMC 250 | 5 HMC 320 |

|---|---|---|---|---|---|

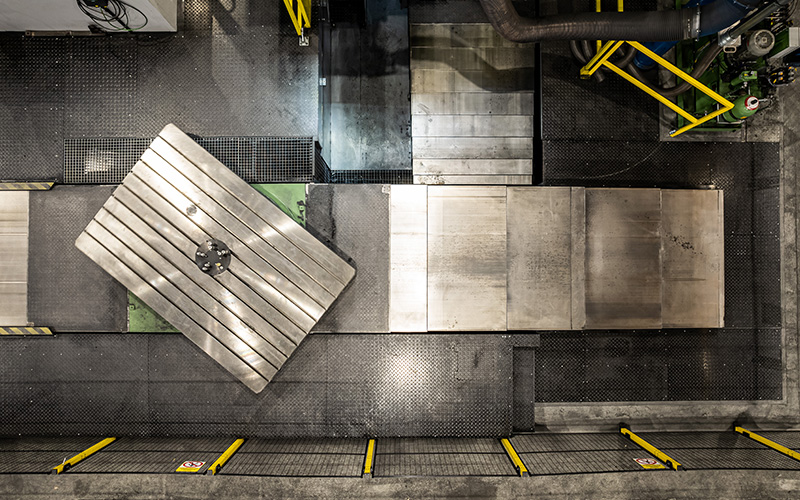

| Rotary table | mm | 1.000 x 1.200* | 1.600 x 1.800* | 1.600 x 2.500* | 2.000 x 3.200* |

| Spindle power | kW | 19,5 | 30 | 44 | 61 |

| Spindle speed | rpm | 10 - 1.050 | 10 - 1.050 | 10 - 600 | 10 - 600 |

| Max. torque | Nm | 1.050 | 1.600 | 5.900 | 7.500 |

| Max. tool diameter | mm | 400 | 600 | 900 | 1.100 |

| Spindle swiveling range | deg. | +20o / -5o | +20o / -5o | +30o / -5o** | +30o / -5o** |

| Tool taper | ISO 50 | ISO 50 / 60 | ISO 50 / 60 | ISO 60 |

* other table sizes available on request

** +30⁰ / -30⁰ available on request

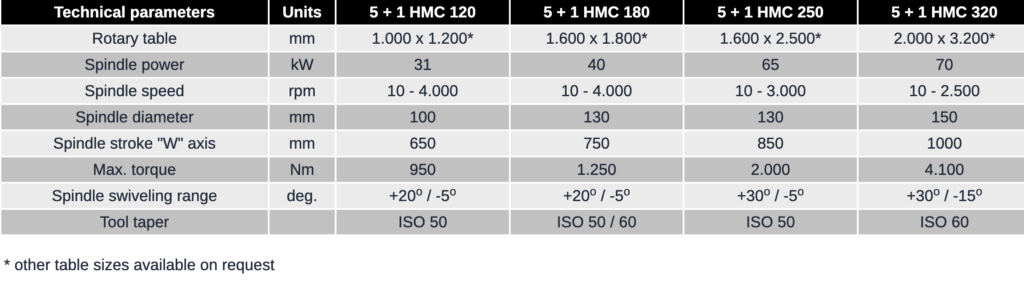

5 +1 HMC

5+1 HMC is a 6 axis swiveling boring mill dedicated for heavy cutting. It is a unique solution thanks to combining the swiveling spindle unit with a boring bar.

5 +1 HMC

TECHNICAL

SPECIFICATION

| Technical parameters | Units | 5 + 1 HMC 120 | 5 + 1 HMC 180 | 5 + 1 HMC 250 | 5 + 1 HMC 320 |

|---|---|---|---|---|---|

| Rotary table | mm | 1.000 x 1.200* | 1.600 x 1.800* | 1.600 x 2.500* | 2.000 x 3.200* |

| Spindle power | kW | 31 | 40 | 65 | 70 |

| Spindle speed | rpm | 10 - 4.000 | 10 - 4.000 | 10 - 3.000 | 10 - 2.500 |

| Spindle diameter | mm | 100 | 130 | 130 | 150 |

| Spindle stroke "W" axis | mm | 650 | 750 | 850 | 1000 |

| Max. torque | Nm | 950 | 1.250 | 2.000 | 4.100 |

| Spindle swiveling range | deg. | +20o / -5o | +20o / -5o | +30o / -5o | +30o / -15o |

| Tool taper | ISO 50 | ISO 50 / 60 | ISO 50 | ISO 60 |

* other table sizes available on request

Horizontal machine tools

OPTIONS

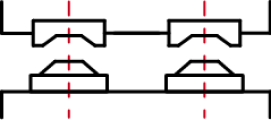

Wide range of automatic tool change devices give us the flexibility to adapt to every technological process.

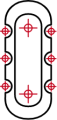

Zero point clamping system is used for our pallet clamping/alignment. With the clamping systems and accompanying clamping bolts, maximum precision in the repeatability of the clamping position is achieved. Our clamping system is made as a quadruple application to give our customers max. positioning precision.

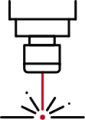

Renishaw probe for measuring the work piece before and after machining.

Customized solutions available to suit particular technological requirements.

All our 5HMC are prepared for the installation of the dust extraction systems.

Wide range of automatic tool change devices give us the flexibility to adapt to every technological process.

Zero point clamping system is used for our pallet clamping/alignment. With the clamping systems and accompanying clamping bolts, maximum precision in the repeatability of the clamping position is achieved. Our clamping system is made as a quadruple application to give our customers max. positioning precision.

Renishaw probe for measuring the work piece before and after machining.

Customized solutions available to suit particular technological requirements.

All our 5HMC are prepared for the installation of the dust extraction systems.