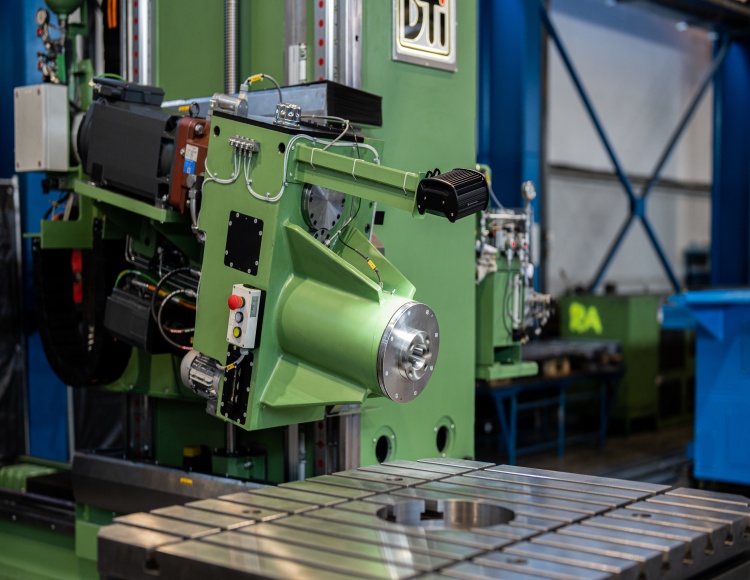

The smallest machining center from 5HMC family successfully delivered

5HMC machining centers offer the highest productivity and precision for the heavy duty cutting. The smallest in the family 5HMC120CNC can machine the workpiece 1000mm x 1200mm and is prepared for ISO 50 tools (all other 5HMC work with ISO 60).

However, the key concept of the 5HMC design can be seen also here:

- all main components made of grey iron castings

- “A” and “B” axis master slave type

- rigid design to ensure tight tolerance to be maintained over time

- media supplied thru the center of the table and spindle

- hydro – mechanical clamps for clamping the rotary table in the working position

- swiveling spindle unit (“A” axis)

- Heidenhain linear and rotary scales.

With the biggest 5HMC320CNC we can achieve the impressive max torque of 7500 Nm and effectively

machine parts up to 25 tons with 60kW (S1) spindle power using tools up to 1100mm diameter.

The smallest version 5HMC120CNC offers respectively 1050 Nm, 5 tons, 19.5kW and 400mm diameter tools.

No matter what table size is chosen the 5HMC is delivering unique quality standards for machining

with ISO 60 tools:

- positioning accuracy for “X”, “Y” and “Z” axis ±0.01 mm/1m

- repeatability for “X”, “Y” and “Z” axis ±0.008 mm

- angular positioning accuracy for “A” and “B” axis ±0.0015 deg.

- angular repeatability for “A” and “B” axis ±0.0010 deg.

The 5HMC family offers a wide choice of optional equipment. Not only the standard options like tool

changers or workpiece probing. Also pallet systems and dust extraction systems.

Three 5HMC machining centers are already installed at Tokai Cobex. This confirms 30 years of DTI

experience in providing the customized solutions for the carbon industry. Nowadays we offer state

of the art machine tools dedicated for cathode blocks, nipples and furnace linings.