What’s new

We are launching the DTI TechAcademy – discover with us the secrets of designing heavy-duty machine tools

DTI TechAcademy this project aims to introduce the world of heavy DTI machine tools. As part of our training center – on the website DTI TechAcademy, we will present comprehensive, substantive materials focusing on one of the features of heavy machine tools, we will discuss many issues related to the proper design, production and modernization...

We would like to invite you to read the January issue of BusinessPl, where you will learn, among others, about the beginnings, evolution and flagship projects of DTI.Karolina Sywak, Managing Director, will present the history of the company

Design Technologies International Sp. z o. o. (DTI) – Three decades of innovation in the world of special machine tools. Design Technologies International Sp. z o. o., known as DTI, is a company based in Racibórz, which has been proudly operating in the industry of special heavy duty machine tools since 1991. DTI supplies machine tools perfectly tailored...

Modernization for the world leader in the production of machines for the paper industry

We have just completed the modernization of a milling machine with a movable crossrail manufactured by WALDRICH SIEGEN PORĘBA in 1972. Our client, a leader in the production of machines for the paper industry, can again machine complex workpieces with max dimensions of 1600mm x 8000mm x 2000mm. After signing the contract, we spent the first 8 months...

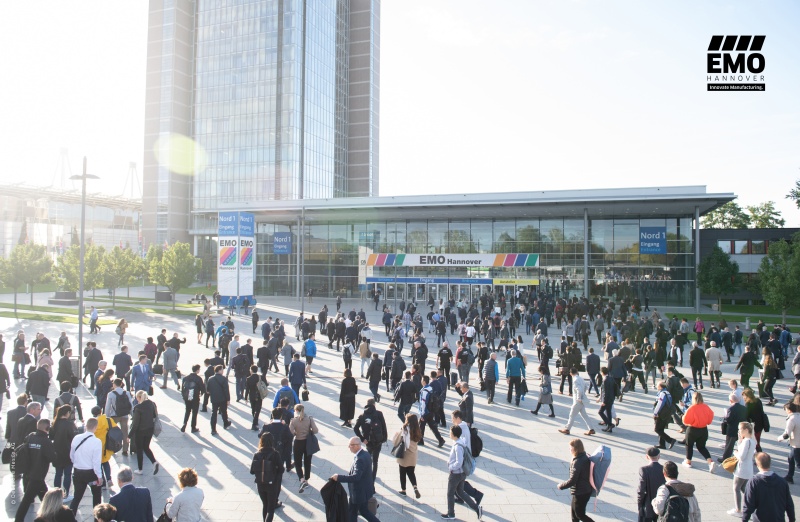

EMO 2023 is behind us

We are extremely grateful for all the valuable comments, insightful conversations and new contacts we have established. Your support fuels our commitment to providing custom, heavy-duty machine tools tailored to your needs. Please don’t hesitate to contact us if you have any questions or need more information. We are here for you! Let’s continue the...

32 Years on the Market – About Technology, Changes, and Relationships that Lead to Success [INTERVIEW WITH KAROLINA SYWAK]

We invite you to watch a special interview with Karolina Sywak, Managing Director of DTI. We will take you on a sentimental-business journey through the heavy machinery market, to which we, as DTI Machine Tools, joined over 30 years ago! The industrial market in Poland and around the world is changing rapidly – this is, of course,...

Our Collaboration with Ingersoll – Shaping New Horizons in the World of Production

We are delighted to share with our community a significant achievement. The latest issue of the esteemed “Manufacturing Today” magazine shed light on our dynamic collaboration with the renowned company Ingersoll. Ingersoll, as an outstanding industry leader, acknowledged our partnership in an article, which is a tremendous honor for us. The article emphasizes that our joint work...

Visit the home of technology! Join the EMO Hannover 2023

World’s leading trade fair for production technology is coming! EMO Hannover is the perfect opportunity to get to know the innovative DTI offer, meet our experts and talk about the best technological solutions for your company. Let’s meet at EMO Hannover Expert knowledge, the latest technological solutions and individual ways to develop your own business,...

Next door modernization

The project that we have recently implemented was very close to us. And I’m not talking about the distance separating us from the client, the implementation took place two streets from our workshop, but the “closeness” (to our heart) was primarily influenced by the fact that at the place were already four of our machines....

Smart chamfering

A leader in the energy industry turned to us to solve a bottleneck in its production cycle. The shell and tube heat exchangers manufactured by it require thousands of holes in the sheets and baffles. Each hole must be chamfered, which requires accurate identification of the position of the previously drilled hole. An additional requirement was the...

Perfection in modernization

15 years ago, a customer from the railway industry asked us to upgrade an old Waldrich Coburg planer into a modern CNC milling machine. The machine was to be used for machining Hadfield steel (production of railway crossings and switches). We used only the basic bodies (bed and table) from the old machine. We equipped the machine...

DTI at AMB in Stuttgart

We would like to take this opportunity to thank all our customers and partners for visiting our booth A52 , Hall 9 at this year’s AMB International Exhibition for Metal Working in Stuttgart. We hope you enjoyed the show and we look forward to seeing you again in the near future. We are always at your...

5+1 HMC nominated for MM Award

We are pleased to announce that our new product swiveling boring mill type 5 + 1 HMC has been nominated for the MM Innovation Award at the AMB fair in Stuttgart in the Machine tools category. It proves that we have rightly chosen the path of designing customized heavy duty machinetools. WE INVITE YOU TO VOTE ...

DTI launch a unique family of heavy-duty 5+1 HMC swiveling boring mills

5HMC series is an answer to the demands of the customers who need the highest productivity also for heavy-duty machining. Prepared for ISO 50 and ISO 60 tools with an impressive max torque of 7500 Nm this new design allows to effectively machine parts up to 25 tons. It can be configured with the max spindle power of...

The smallest machining center from 5HMC family successfully delivered

5HMC machining centers offer the highest productivity and precision for the heavy duty cutting. The smallest in the family 5HMC120CNC can machine the workpiece 1000mm x 1200mm and is prepared for ISO 50 tools (all other 5HMC work with ISO 60). However, the key concept of the 5HMC design can be seen also here: all...

Before and after – another successful modernization

Another cost-efficient modernization successfully completed by DTI team. Waldrich Coburg planer mill produced in 1979 has been under the extensive modernization process for over 1 year and now it can again ensure the rigidity and precision for the next decades. We completed several mechanical works on the machine. A new modified spindle with super precision ball bearings...

Tailor-made modernization of old Waldrich Coburg milling machine

When our customer to whom we have already delivered 4 heavy duty planer mills said he was looking for another one but with a lower budget we started looking for a solution. We found on the market an old Waldrich Coburg milling machine from 1985 listed for sale and made the offer. One year later this completely modernized milling machine...

DTI launch the new family of heavy-duty 5 axis machining centers 5HMC

5HMC is the answer to the demands of the customers who need highest productivity also for heavy-duty machining. Prepared for ISO 60 tools with an impressive max torque of 7500 Nm this new design allows to effectively machine parts up to 25 tons. It can be configured with the max spindle power of 60kW. As...

Efficient and economical solution

DTI successfully modernized a 40-year-old Voestalpine planing machine into a modern PLATE EDGE MILLING MACHINE for a world known energy sector customer. Usually this kind of machines are used to machine large flame cutting plates in preparation for welded constructions. The machine is now faster, more reliable, obtains a high precision and applies with the current safety rules. After the...