Products

Lathes

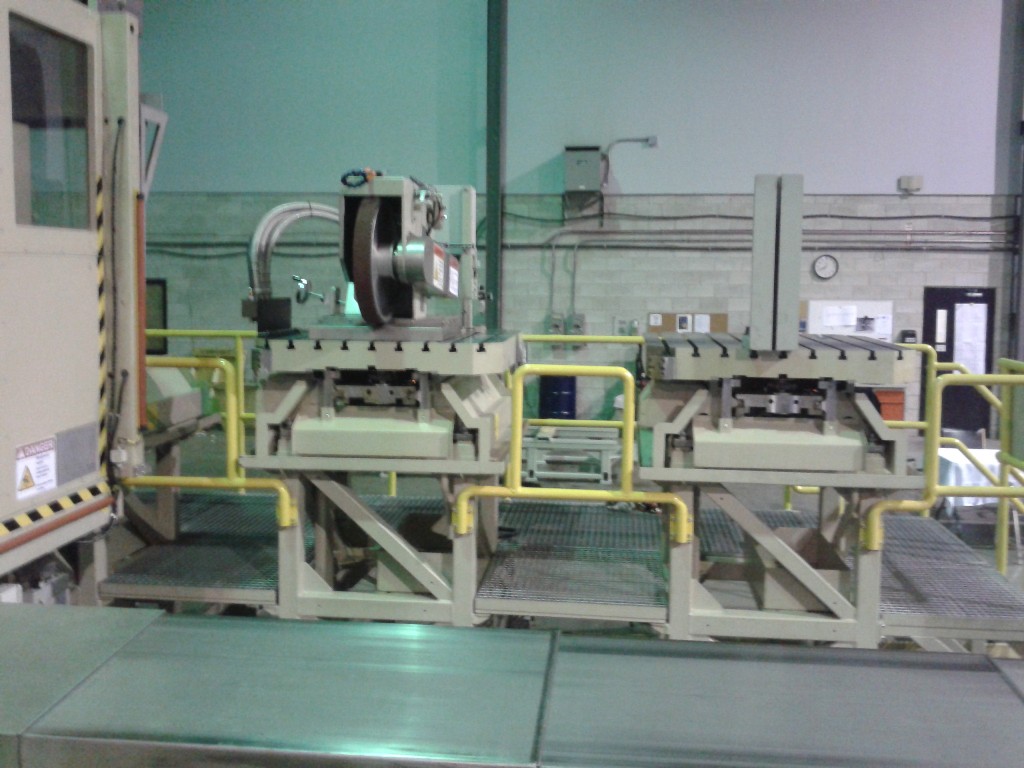

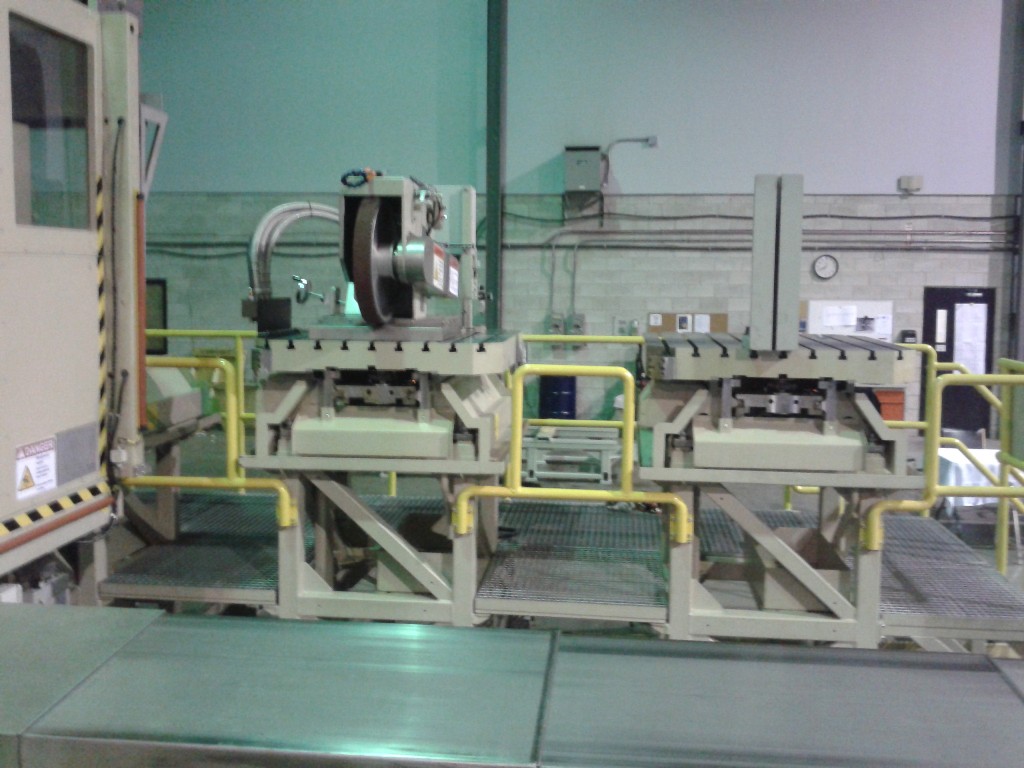

All our heavy-duty lathes we can configure as a custom machine solutions with a wide range of options. For small and medium lathes please visit the website of FAT HACO

Lathes

MAIN FEATURES

- All main body components made of grey iron casting

- High rigidity ensures tight tolerance maintained over time

- 4-way step bed design

- Steel, hardened and ground slide ways

- Ball screws dia 100mm

- Square quill up to 800mm x 800mm

- Up to 100 tons between centers without steady rests

Lathes

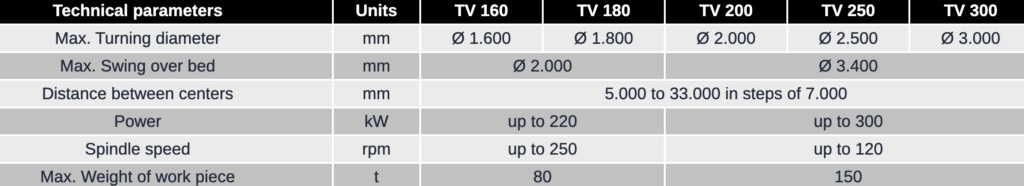

TECHNICAL

SPECIFICATION

| Technical parameters | Units | TV 160 | TV 180 | TV 200 | TV 250 | TV 300 |

|---|---|---|---|---|---|---|

| Max. Turning diameter | mm | Ø 1.600 | Ø 1.800 | Ø 2.000 | Ø 2.500 | Ø 3.000 |

| Max. Swing over bed | mm | Ø 2.000 | Ø 3.400 | |||

| Distance between centers | mm | 5.000 to 33.000 in steps of 7.000 | ||||

| Power | kW | up to 220 | up to 300 | |||

| Spindle speed | rpm | up to 250 | up to 120 | |||

| Max. Weight of work piece | t | 80 | 150 | |||

Lathes

OPTIONS

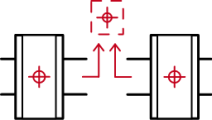

Wide range of manual and CNC steady rests of different type.

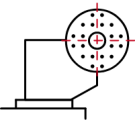

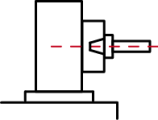

Our grinding head is a full CNC solution with the possibility of automatic balancing of the grinding wheel.

The drilling / milling head comes in combination with a B-axis.

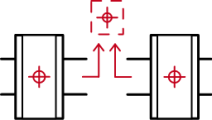

All optional equipment can be mounted on a pallet. Depending on the operations, the pallets are changed automatically.

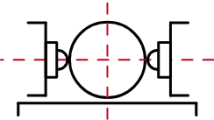

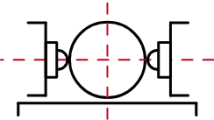

The CNC unit can be mounted on the same guideways as the tailstock and is driven by a ball screw. The two rolls are controlled by hydraulic pressure up to 30t each.

Wide range of manual and CNC steady rests of different type.

Our grinding head is a full CNC solution with the possibility of automatic balancing of the grinding wheel.

The drilling / milling head comes in combination with a B-axis.

All optional equipment can be mounted on a pallet. Depending on the operations, the pallets are changed automatically.

The CNC unit can be mounted on the same guideways as the tailstock and is driven by a ball screw. The two rolls are controlled by hydraulic pressure up to 30t each.