Products

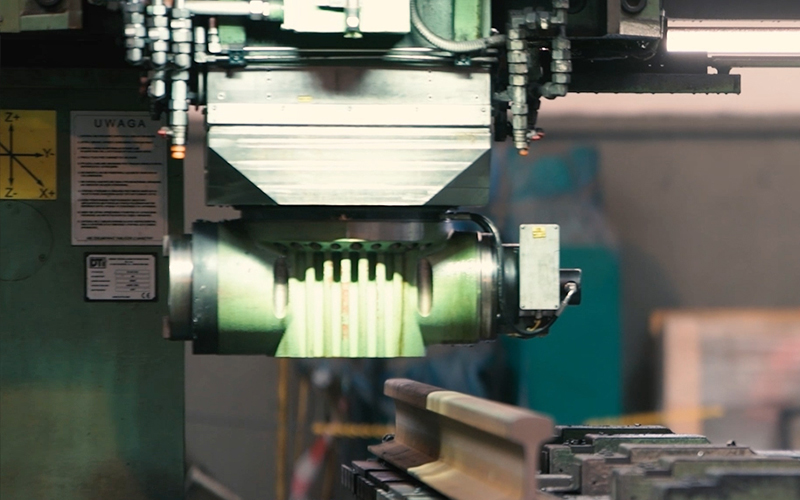

FB

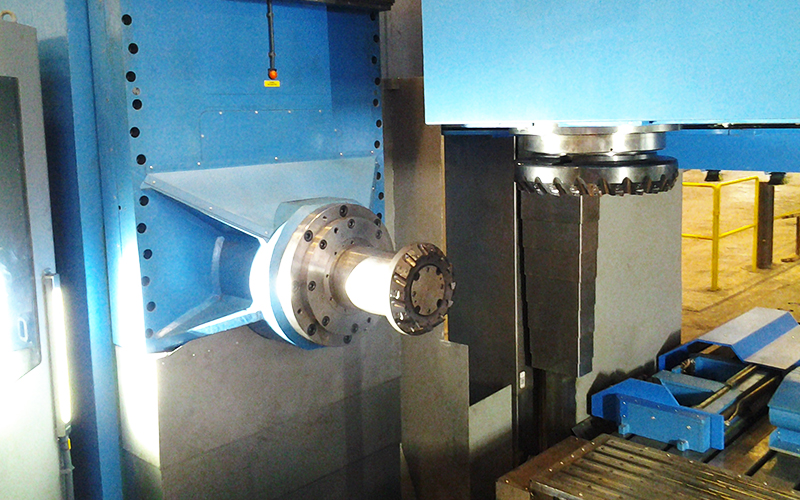

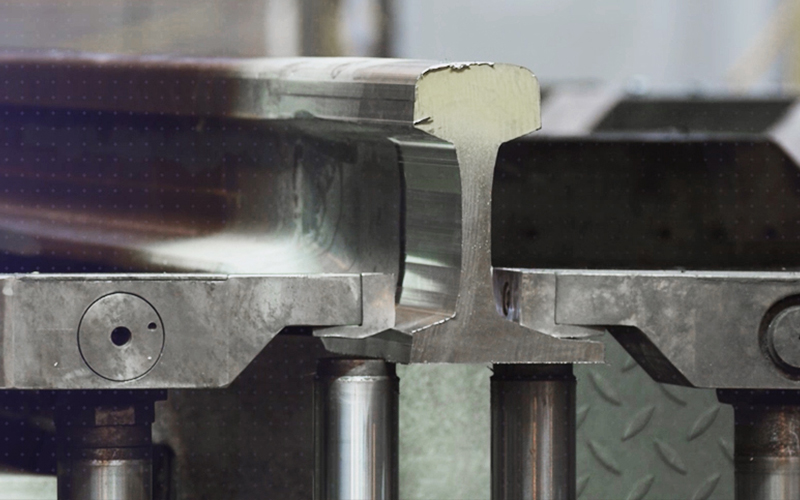

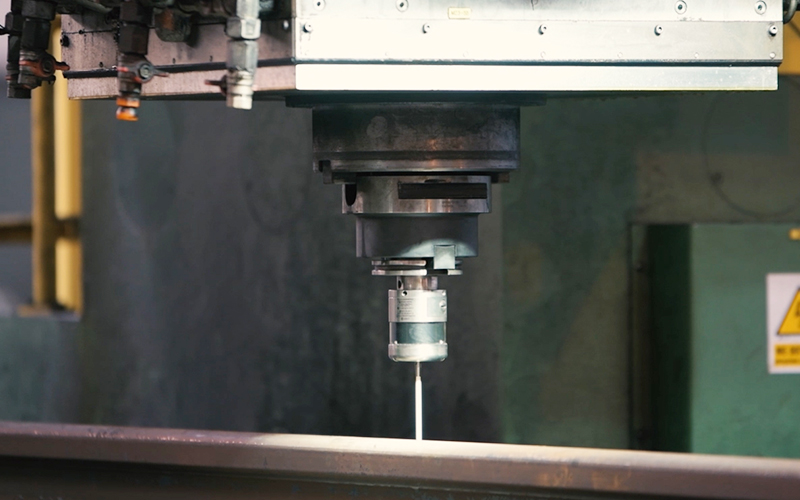

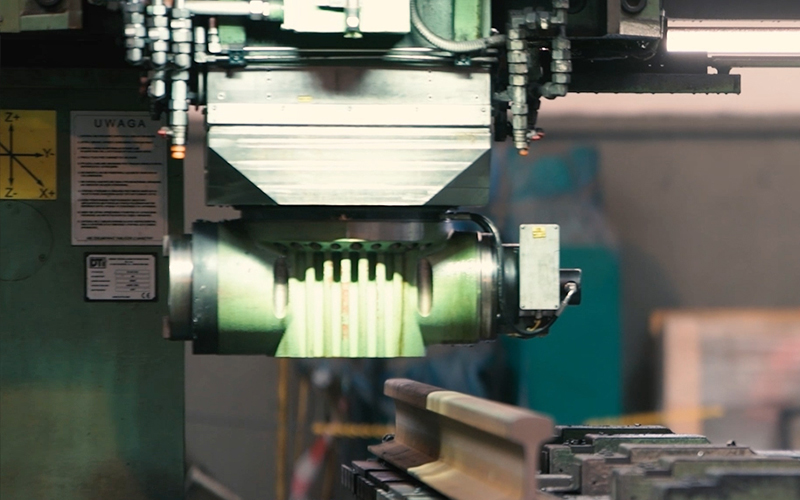

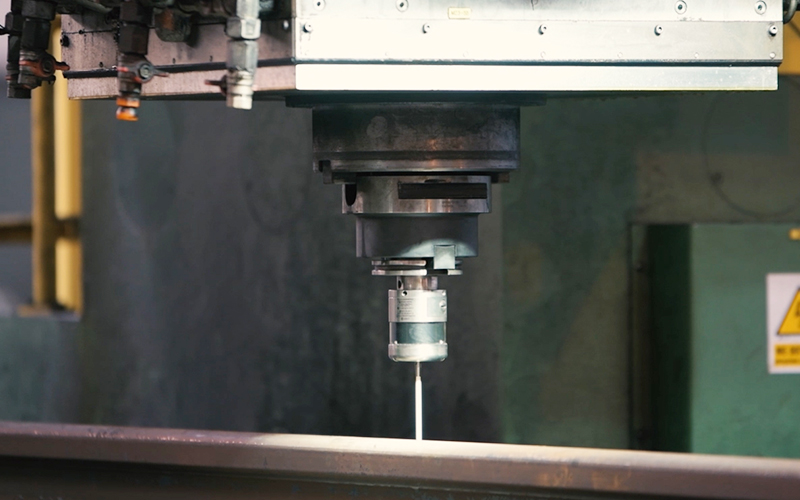

Heavy-duty medium and large size milling machines suitable for machining tough materials.

The FB range is also available in gantry design.

Vertical machine tools

MAIN FEATURES

- All main components made of grey iron casting

- High rigidity ensures tight tolerance maintained over time

- Hardened and ground slide ways

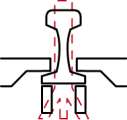

- Doubled feed drive for vertical travel of ram including 2 preloaded ball screws, 2 planetary gear boxes and 2 AC Siemens servomotors

- 3 ways support of the vertical head for horizontal movement

- Heidenhain linear scales for all CNC axes

- Fixed or moving cross rail

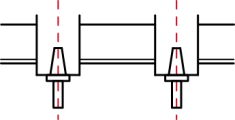

- Up to 10m table is driven by a ball screws supported by a patent solution in a combination with a backlash free planetary gearbox

- From 10m table is driven by rack and pinion (master / slave)

Vertical machines tools

TECHNICAL

SPECIFICATION

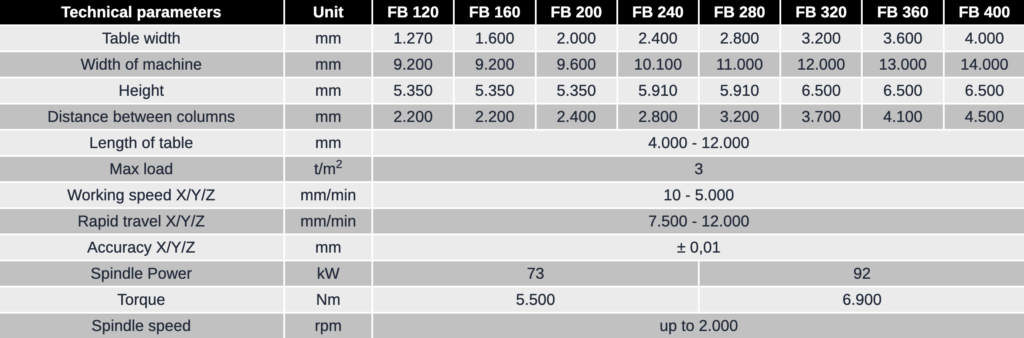

| Technical parameters | Unit | FB 120 | FB 160 | FB 200 | FB 240 | FB 280 | FB 320 | FB 360 | FB 400 |

|---|---|---|---|---|---|---|---|---|---|

| Table width | mm | 1.270 | 1.600 | 2.000 | 2.400 | 2.800 | 3.200 | 3.600 | 4.000 |

| Width of machine | mm | 9.200 | 9.200 | 9.600 | 10.100 | 11.000 | 12.000 | 13.000 | 14.000 |

| Height | mm | 5.350 | 5.350 | 5.350 | 5.910 | 5.910 | 6.500 | 6.500 | 6.500 |

| Distance between columns | mm | 2.200 | 2.200 | 2.400 | 2.800 | 3.200 | 3.700 | 4.100 | 4.500 |

| Length of table | mm | 4.000 - 12.000 | |||||||

| Max load | t/m2 | 3 | |||||||

| Working speed X/Y/Z | mm/min | 10 - 5.000 | |||||||

| Rapid travel X/Y/Z | mm/min | 7.500 - 12.000 | |||||||

| Accuracy X/Y/Z | mm | ± 0,01 | |||||||

| Spindle Power | kW | 73 | 92 | ||||||

| Torque | Nm | 5.500 | 6.900 | ||||||

| Spindle speed | rpm | up to 2.000 | |||||||

Two milling spindles possible from FB 240

Vertical machines tools

OPTIONS

Depending on the number of tools we offer a disk, chain or rack in combination with robot arm. In addition, a custom designed tool changer can be provided.

To maintain a high torque, we developed and produce the Angular heads in house. Our Angular heads can handle up to 5100Nm torque. Next to fix angular heads we also offer swiveling heads with a position angle of each 5° up to 0, 5°. In the range of milling heads, we also offer units with special shapes to have better access on difficult accessible work faces. The different heads are locked by a Hirth and clamped on the spindle by hydraulic pressure.

The complexity of different work pieces requires a large number of optional milling heads. Thanks to the Head Changer, milling heads can be stowed and changed automatically.

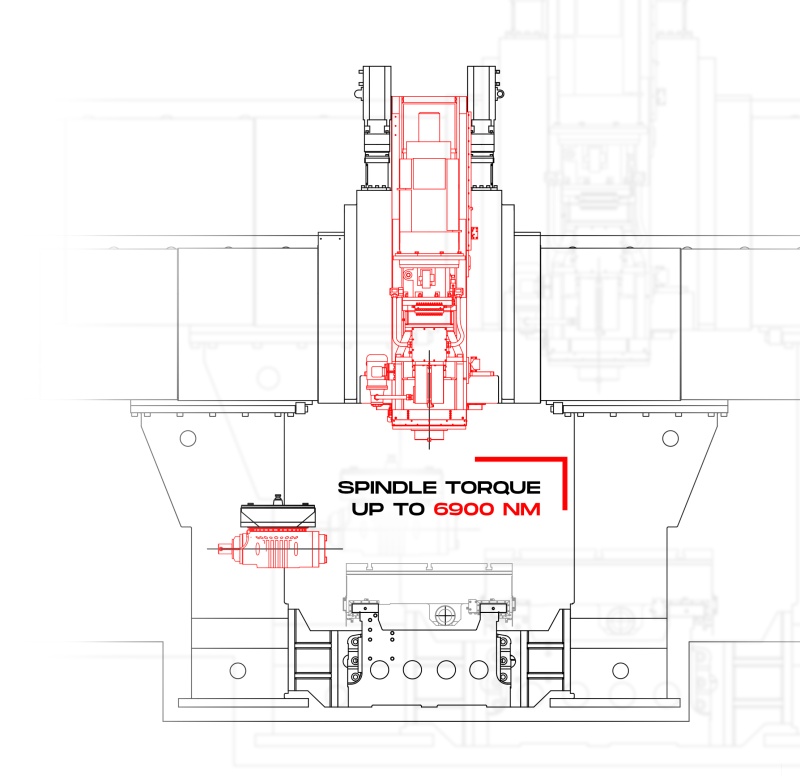

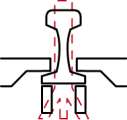

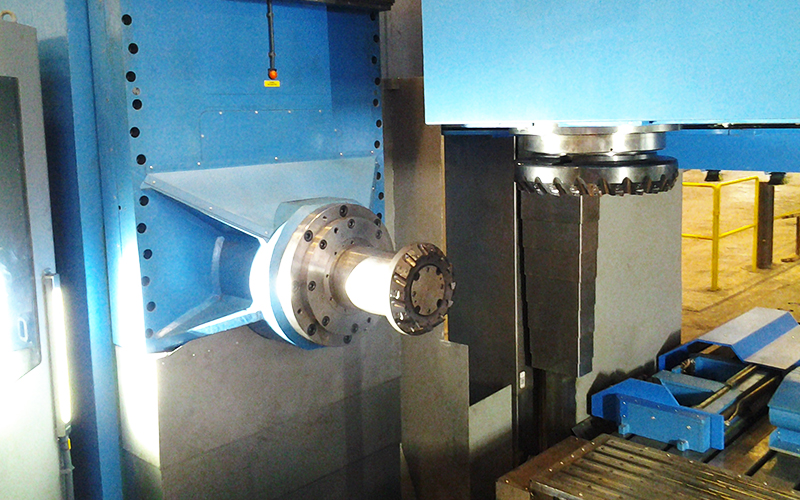

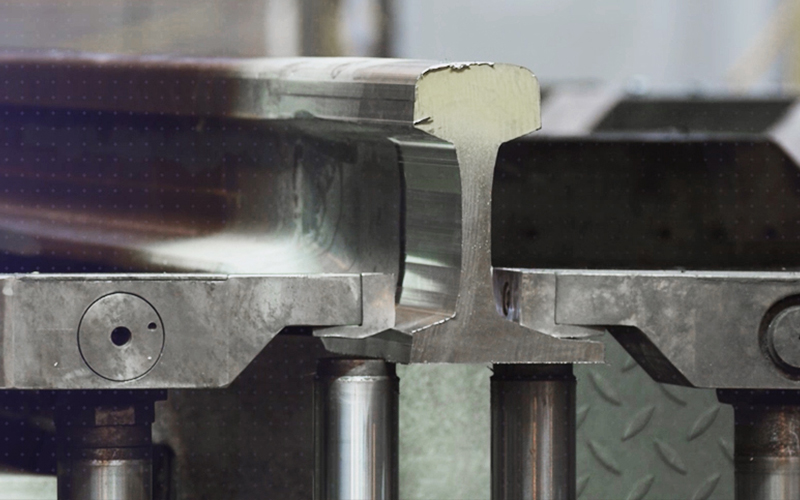

The modular design of the FB range machine tools creates the possibility to add a second spindle. Both spindles can work simultaneously.

Depending on the specific characteristic of the work piece we have developed several clamping solutions, in order to reduce repositioning of the work piece and to have better accessibility. The clamps are designed to handle a high torque during operation.

Machine can be equipped optionally with movable crossrail to obtain optimal stroke of Z-axis during the machining.

Renishaw probe for measuring the work piece before and after machining.

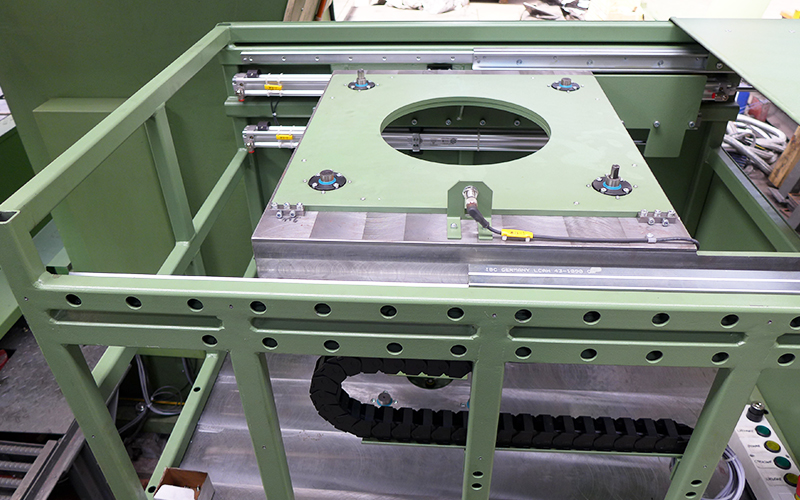

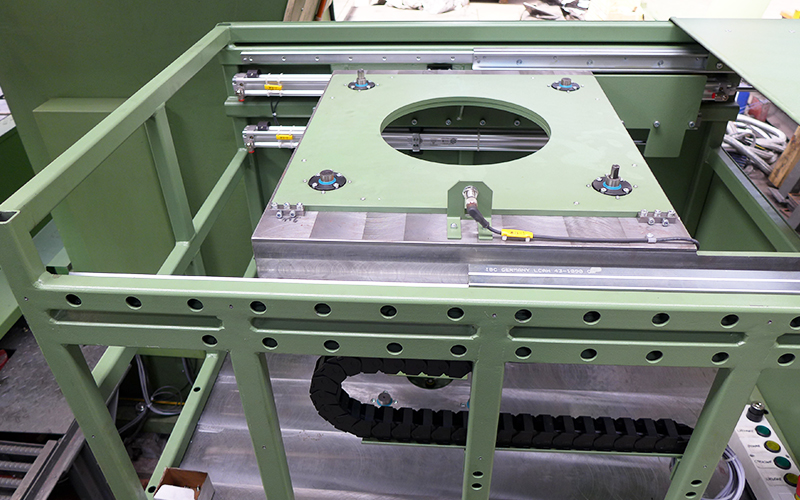

Vertical milling machines can be equipped optionally with rotary tables.

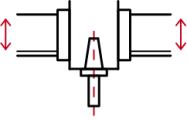

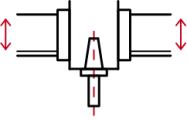

Vertical milling machines can be equipped optionally with an additional horizontal spindle installed on a side column and working simultaneously with the vertical one.

Depending on the number of tools we offer a disk, chain or rack in combination with robot arm. In addition, a custom designed tool changer can be provided.

To maintain a high torque, we developed and produce the Angular heads in house. Our Angular heads can handle up to 5100Nm torque. Next to fix angular heads we also offer swiveling heads with a position angle of each 5° up to 0, 5°. In the range of milling heads, we also offer units with special shapes to have better access on difficult accessible work faces. The different heads are locked by a Hirth and clamped on the spindle by hydraulic pressure.

The complexity of different work pieces requires a large number of optional milling heads. Thanks to the Head Changer, milling heads can be stowed and changed automatically.

The modular design of the FB range machine tools creates the possibility to add a second spindle. Both spindles can work simultaneously.

Depending on the specific characteristic of the work piece we have developed several clamping solutions, in order to reduce repositioning of the work piece and to have better accessibility. The clamps are designed to handle a high torque during operation.

Machine can be equipped optionally with movable crossrail to obtain optimal stroke of Z-axis during the machining.

Renishaw probe for measuring the work piece before and after machining.

Vertical milling machines can be equipped optionally with rotary tables.

Vertical milling machines can be equipped optionally with an additional horizontal spindle installed on a side column and working simultaneously with the vertical one.