Products

GMC

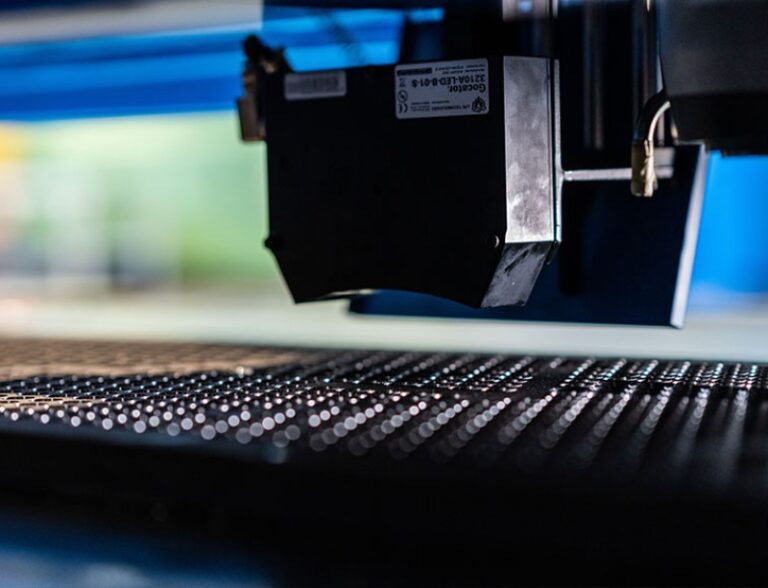

The shell and tube heat exchangers require thousands of holes in the sheets and baffles. Each hole must be chamfered, which requires accurate identification of the position of the previously drilled hole. We offer gantry machine with 2 milling – chamfering – drilling vertical units. Each of the vertical units has a 3D laser scanner that is integrated with the CNC system of the machine tool. This allows us to make each hole with an accuracy of +/- 0.1mm (in each plane). After scanning the detail, a machining program is generated automatically (the operator’s task is limited to clamping the work piece and determining the base point).

Vertical machine tools

MAIN FEATURES

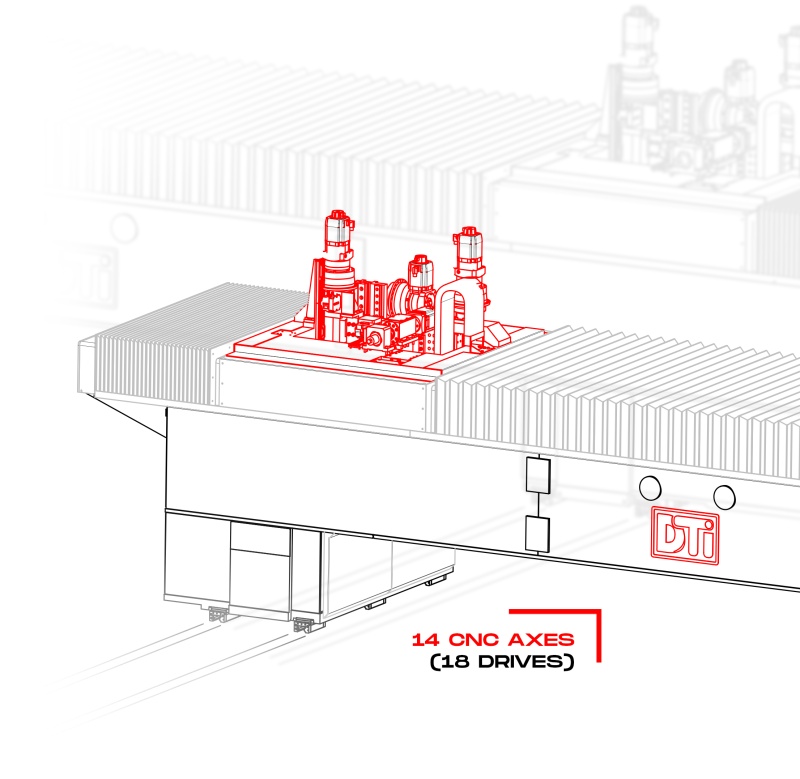

- 14 CNC axes on one machine tool (18 drives)

- Each of two vertical machining units has 6 CNC axes

- Unique solution that allows the spindle to move by ± 46mm in the “X” axis and ± 100mm in the “Y” axis without the need to move the crossrail

- Advanced scanners to identify hole positions before machining

- Automatic correction of the machining program with the data sent from the scanners

- Two 16-positions tool changers

- Heidenhain linear scales in all axes

- Strongly ribbed welded crossrail

- Set of pressure cylinders to eliminate vibrations during the machining

- Integrated cooling system through and on the spindle

- Measurement of spindle bearings temperature

- “X” axis – a doubled master-slave system with backlash compensation

- “Z” axis consists of two ball screws ensuring perfect rigidity and positioning repeatability

Vertical machine tools

TECHNICAL

SPECIFICATION

| Technical parameters | Units | GMC |

|---|---|---|

| Max diameter of the drilled hole | mm | 50 |

| Spindle power | kW | 10.5 |

| Rotary speed of spindle | rpm | 100 - 2500 |

| Max "X" axis travel | mm | 10 000 |

| Max distance between columns | mm | 8 000 |

| Rapid travel | m/min2 | 15 |

| Tool taper | ISO 40 |